Description

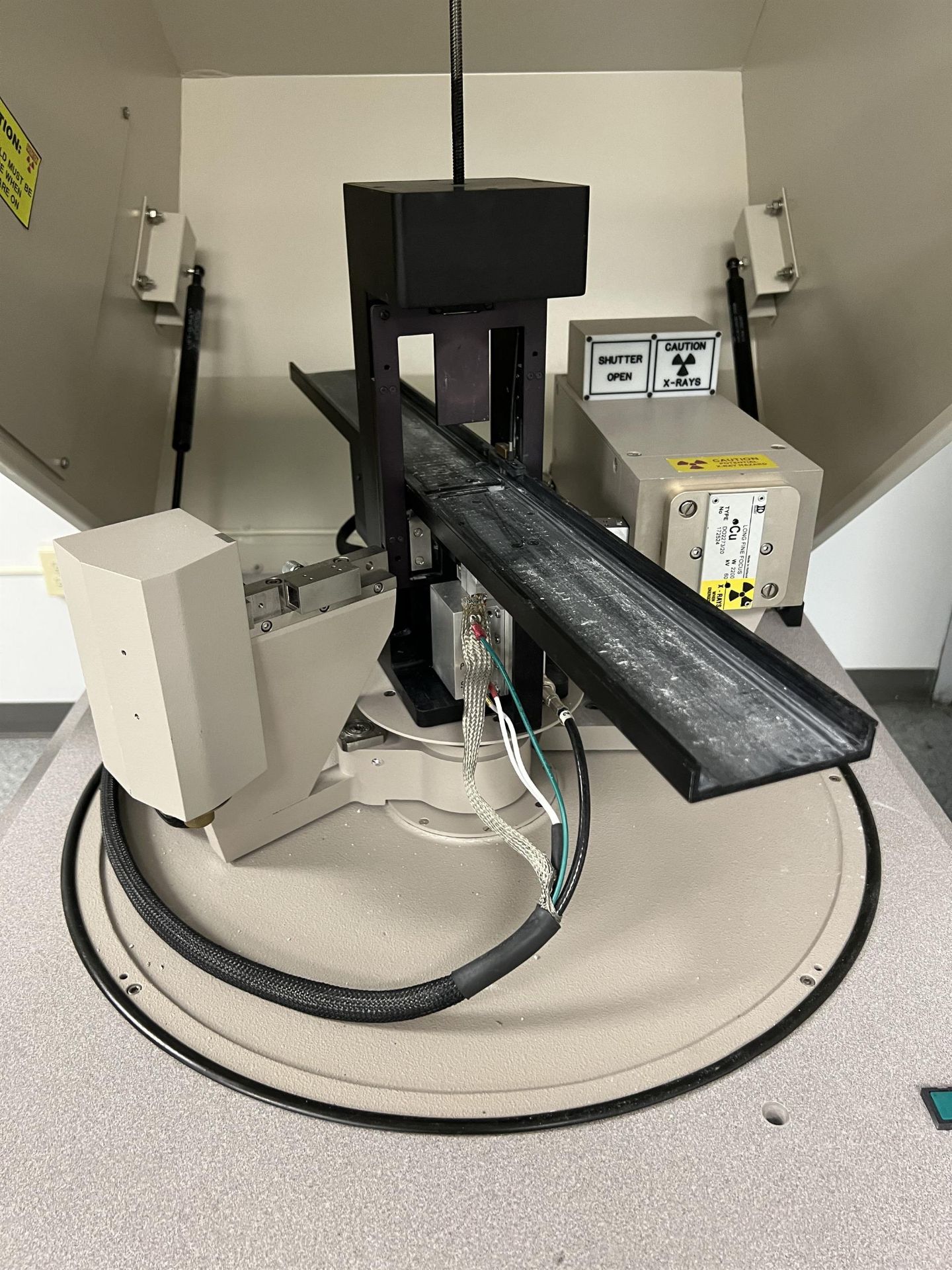

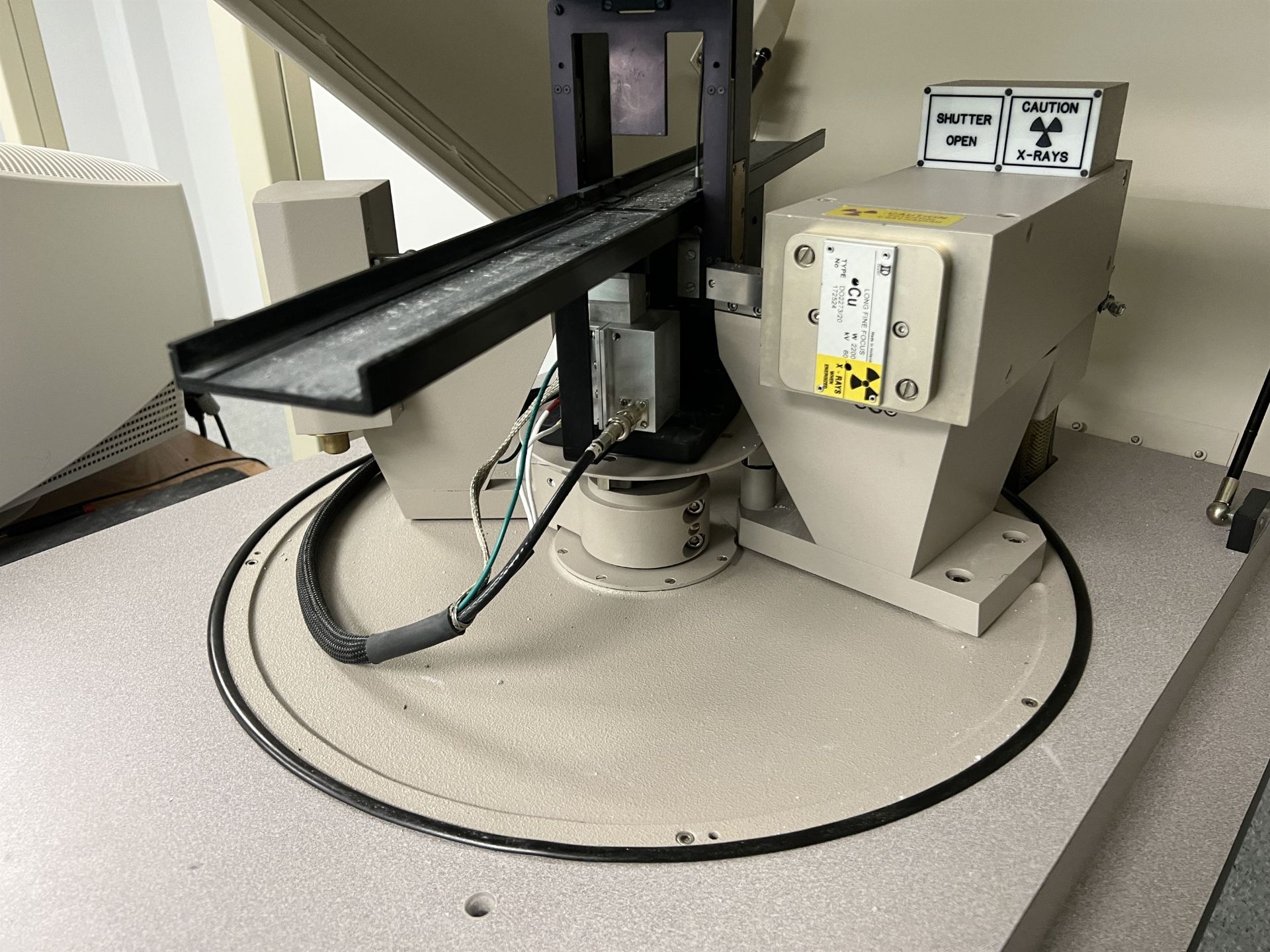

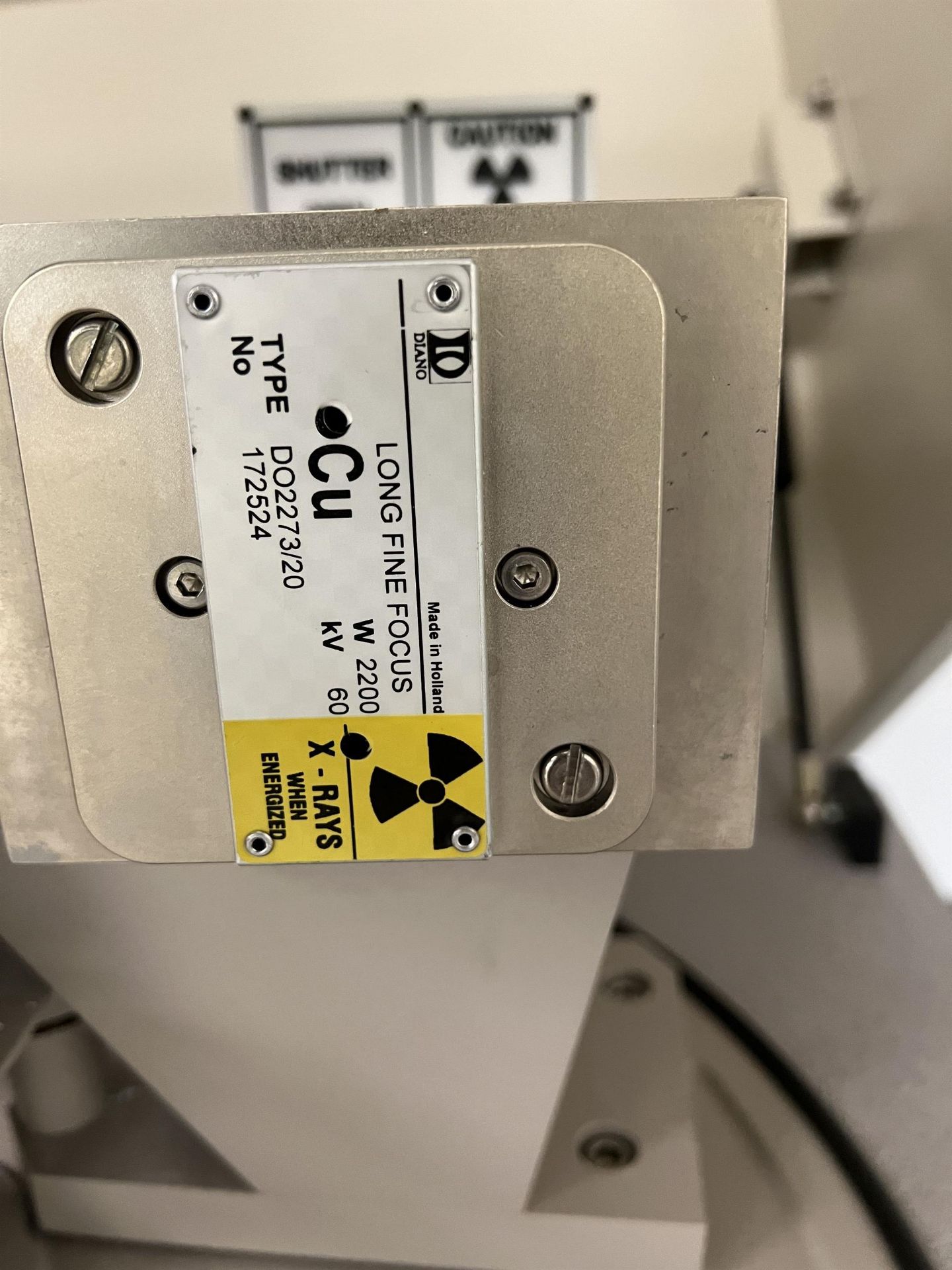

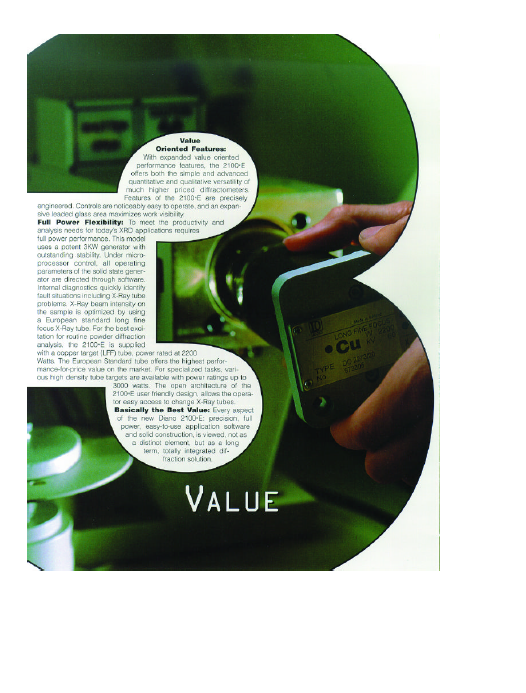

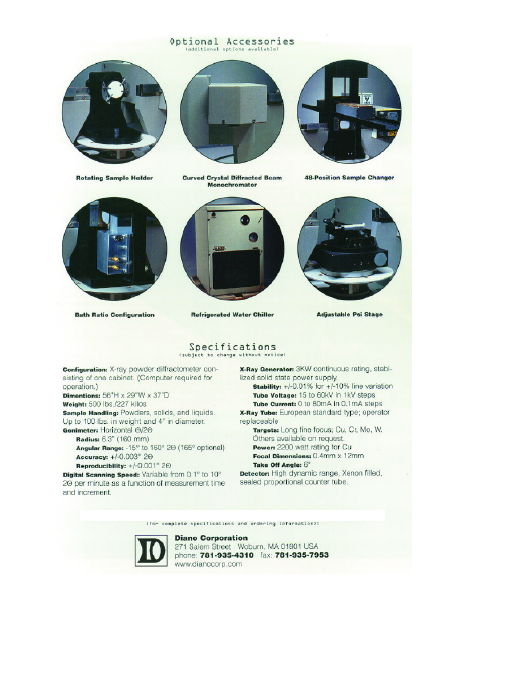

Manufactured by Diano, https://www.dianocorp.com/ , of Wolburn Massachusetts USA

Includes manuals and many dozens of sample holders. Excellent condition.

For software, I recommend writing your own bins using Excel spreadsheet or Open Office Calc. A tutorial is available, please email me for a copy.

[Best_Wordpress_Gallery id=”2″]

DIANO X-Ray Diffraction systems are used in a wide variety of applications. Diffraction is one of the most powerful methods available for fundamental research, product development and production control. As a non-destructive procedure, DIANO Diffraction systems are used throughout industry, education and independent laboratories. The following list gives you a sample of the many and diverse diffractometer applications solved by DIANO today.

- Furnish a unique and unquestionable characterization of individual chemical compounds.

- Qualitative and quantitative determination of compounds in a mixture.

- Positive identification of the phases of identical chemical formula but differing in crystal structure and in physical properties.

- A non-destructive method of determining residual surface stresses in metals.

- Identification of inclusions in metals.

- Determination of the amount of retained austenite in alloy steels.

- Study of the mechanism of fatigue and other types of metal failure.

- Study of precipitation and hardening.

- Study of relations between time and temperature of anneal.

- Determination of quench and temper structures of spring steel.

- Determination of the structure of welds and the presence of strains or distortion.

- Determination of the structure and chemical changes occurring during sintering, fusing and other thermal treatments.

X-RAY DIFFRACTION APPLICATIONS

- Identification of alloy components.

- Routine determination of percentage composition of solid solution phases on the basis of measurement of line shift.

- Determination of phase diagrams of alloy systems.

- Determination of crystallite size and orientation accompanying hot or cold working of materials.

- Study of effect of grain size and composition of rolled strip.

- Determination of slip planes, fiber structure, etc., of rolled sheet and drawn wire.

- Study of zonal structure characteristics as between surface and interior structures.

- Furnishes explanation of structural failures in spinning, cupping and stamping operations.

- Measurement of the depth of cold work caused by machining, drilling, punching, grinding, etc.

- Identification of different types of synthetic rubber and differentiation from natural rubber.

- Study of chemical reactions during the vulcanization and other processing of rubber goods.

- Measurement of crystal size, preferred orientation and thickness of electro-deposited films.

- Determination between true and false hydrates.

- Study of the mechanism of catalysts.

- Determination of the mechanism of reactions and transformation in solid state at high and low temperatures.

- Identification, classification and evaluation of ores, clays and other minerals.

- Identification of substances imparting color and or opacity to glasses or enamels.

- Study of the degree of crystallinity of glass and other quasi amorphous materials.